Table of Contents:

- What Is Ecore Rubber? A Deep Dive into Sustainable, High-Performance Flooring

- What Is Ecore Rubber Made Of? A Look at the Materials and Process

- Sustainable Flooring That Outperforms—By Design

- Why Ecore Rubber Is a Standout in Performance Flooring

- Recycled Doesn’t Mean Compromised: Longevity & Durability

- Comparing Ecore Rubber to Other Flooring Types

- Who’s Using Ecore Materials? Industry Applications

- Why Sustainable Flooring Isn’t Optional Anymore

- Future-Proofing with Ecore Rubber: What’s Next?

- Conclusion: Why Ecore Rubber Is a Game-Changer

- FAQs About Ecore Rubber Flooring

- The Smarter, Stronger Way to Floor

Sustainable flooring isn’t just a trend—it’s fast becoming the standard for modern spaces that care about design, durability, and the environment. And when you hear about a company that turns old vehicle tires into shock-absorbing, slip-resistant, resilient flooring that outperforms many traditional materials? That’s where Ecore rubber enters the conversation.

But this isn’t your average recycled flooring. In fact, here's the twist: the most impressive thing about Ecore rubber isn’t just that it’s made from post-consumer waste; it’s how this eco-friendly flooring actually surpasses virgin materials in real-world performance—whether it’s in a gym, classroom, rehab center, or retail floor.

So if you're planning a project and wondering what is Ecore rubber flooring and why it's gaining so much traction—literally and figuratively—let's dive into how it's made, why it's different, and what makes it worth considering for your next build.

What Is Ecore Rubber Made Of? A Look at the Materials and Process

At the heart of Ecore rubber is one powerful principle: take a problem—like millions of discarded tires—transform it, and turn it into a solution for today’s most demanding environments. The result? A cleaner planet and a more durable floor. So, how does Ecore do it? It starts with source material. Ecore’s flagship products are created from post-consumer automobile and truck tires. These are shredded, cleaned, and processed into pellets that serve as the foundation of the company’s versatile rubber surfacing products. These recycled granules are then subjected to a process known as vulcanization—a chemical curing method that boosts their durability, elasticity, and resistance to wear. This isn’t just a gimmick—it’s science-backed engineering. The result is what Ecore calls (vulcanized composition rubber (VCR)), a highly resilient base layer that stands up to abuse in high-traffic commercial, athletic, healthcare, and industrial settings. Depending on the application, Ecore materials may also incorporate a surface layer made from finely engineered (EPDM (ethylene propylene diene monomer)) rubber granules. These add color, texture, and heightened performance characteristics—especially important in facility spaces where visual design matters as much as physical endurance.Sustainable Flooring That Outperforms—By Design

We don’t often associate sustainability with toughness. But Ecore flips that notion. This eco-friendly flooring isn’t delicate—it’s engineered for punishment. Let’s break down how Ecore rubber excels as a leader in sustainable flooring:- Waste Diversion: Each square foot of Ecore rubber diverts roughly 2 pounds of rubber from landfills. Multiply that across thousands of feet in fitness clubs, schools, and industrial centers, and the environmental impact is massive.

- Lower Energy Inputs: Compared to producing virgin rubber or PVC, recycling rubber uses less processing energy, water, and raw materials.

- Long Product Lifespan: With its ultra-durable construction, Ecore flooring doesn’t just last—it thrives in high-stress environments, reducing the need for frequent replacements and minimizing lifecycle emissions.

Why Ecore Rubber Is a Standout in Performance Flooring

Ecore rubber is fundamentally performance flooring. Designed not only to survive but to serve, every layer adds functionality that competitors struggle to match. The data validates the design. Here’s what sets Ecore apart:- Impact Reduction + Energy Return: According to (product testing), surfaces like Ecore’s Performance Collection offer up to 16.9% force reduction while delivering up to 68.5% energy restitution—an ideal balance for protecting joints while amplifying motion efficiency.

- Slip Resistance (Wet & Dry): Whether it’s sweat-drenched weights or rainy foot traffic, (traction remains top-tier).

- Sound Absorption: In commercial gyms tested by acoustics experts, Ecore rubber provided measurable noise dampening thanks to the resilience of vulcanized rubber and dense underlayment layers.

Recycled Doesn’t Mean Compromised: Longevity & Durability

Many buyers hesitate when they hear "recycled." There's a misconception that reused materials equal lower quality. Ecore busts that myth completely. Here's the truth: Ecore rubber thrives under pressure. Thanks to its vulcanized construction and EPDM surface designs, Ecore floors resist: - Scuffs and Scratches: Ideal for gyms, airports, factories, and high-turnover retail spaces. - Moisture and Mold: Materials resist wicking while remaining breathable ((source)). - Chemical Spill Damage: Ecore rubber outperforms many thermoplastics in resistance to harsh cleaners, oils, and vehicle fluids—critical in industrial settings. And the performance holds up. In fact, (Ecore Performance rolls) are built to sustain 24/7 use while maintaining form and function for decades, not years.Comparing Ecore Rubber to Other Flooring Types

If you're choosing between ecore rubber and other resilient flooring options, here’s how they stack up:| Feature | Ecore Rubber | Vinyl Flooring | Linoleum |

|---|---|---|---|

| Material Source | Recycled tires (post-consumer waste) | Fossil fuel-derived (PVC) | Natural (linseed oil & wood flour) |

| Sustainability | Very high | Low | Moderate |

| Durability | Excellent (impact + chemical resistant) | Moderate (prone to scratches and dents) | Good, but moisture-sensitive |

| Slip Resistance | Very high (even wet) | Moderate | Moderate |

| Cost Over Time | Low (long lifespan) | Mid-range | Mid-range |

| Acoustic Control | Excellent | Poor | Fair |

Who’s Using Ecore Materials? Industry Applications

Ecore rubber surfaces aren’t just limited to gyms. Their versatility makes them a go-to across industries that demand performance, longevity, and sustainability:- Fitness & Athletics: Weight rooms, cardio zones, turf systems, HIIT arenas, locker rooms (https://www.blueskyfitsupply.com/blogs/news/gym-flooring-options-for-home-or-commercial-use).

- Education: School gymnasiums, classrooms, and inclusive play areas benefit from safety cushioning and sound control.

- Healthcare: Rehab clinics, physical therapy rooms, and eldercare facilities use Ecore flooring for its anti-fatigue and slip-resistance perks.

- Retail & Commercial: Chain stores, airport terminals, tech offices, and manufacturing hubs rely on rubber surfacing to minimize maintenance and extend ROI (source).

Why Sustainable Flooring Isn’t Optional Anymore

Green buildings aren't just gimmicks—they’re the future. Modern building codes, consumer expectations, and corporate ESG goals are setting stricter requirements for sustainability. And resilient materials like Ecore fit right in. Here’s what sets this flooring ahead of the curve: - LEED Contribution: Low-VOC emissions and renewable material content help earn green building certifications. - Climate-Positive Manufacturing: By integrating circular economy principles, Ecore reduces cradle-to-grave environmental impact (https://www.blueskyfitsupply.com/blogs/news/ecore-athletic-performance-flooring-guide) - Closed-Loop Potential: Many (Ecore products) are recyclable, continuing the cycle into new flooring products. If your project includes climate goals or carbon reporting, Ecore rubber is more than a match—it’s an asset.Future-Proofing with Ecore Rubber: What’s Next?

The flooring industry is evolving. And Ecore is leading the way with next-gen solutions. Expect advancements like:- Hybrid Blends: New combinations of recycled rubber with bio-based and high-resilience polymers for longer lifespan and design flexibility.

- Smart Surfaces: Anticipate integration of sensors for motion tracking, impact detection, or even energy harvesting.

- Architectural Customization: More colorways and design textures that mimic high-end natural finishes—without sacrificing durability or sustainability.

Conclusion: Why Ecore Rubber Is a Game-Changer

From what it’s made of to how it performs, Ecore rubber proves that sustainability and performance can go hand-in-hand. This isn’t just recycled rubber flooring—it’s performance flooring optimized for real-world challenges. Whether you're outfitting a commercial gym, designing a sustainable school building, or looking for resilient flooring that won’t quit, Ecore delivers. With its long lifecycle, environmentally responsible materials, and unmatched impact performance, it leads the new generation of sustainable flooring that doesn’t just meet spec—it raises the bar. So next time someone tells you "recycled = compromised," just send them to a space where Ecore is underfoot. They'll feel the difference. And so will the planet.FAQs About Ecore Rubber Flooring

1. What is Ecore Rubber made from?

Ecore Rubber is made primarily from recycled automobile and truck tires. These post-consumer tires are shredded, cleaned, and processed into rubber pellets, which are then cured into durable vulcanized composition rubber (VCR).

- Core material: Reclaimed rubber from used tires

- Cured using vulcanization for superior strength

- Optionally topped with EPDM rubber for added design and resilience

Looking for eco-conscious performance flooring? Explore our top picks for Ecore Rubber solutions designed for gyms, schools, and commercial spaces.

2. How does Ecore Rubber compare to vinyl and linoleum for durability and sustainability?

Ecore Rubber outperforms vinyl and linoleum in both durability and environmental impact.

| Feature | Ecore Rubber | Vinyl | Linoleum |

|---|---|---|---|

| Made From | Recycled rubber (tires) | Petroleum-based PVC | Natural materials (linseed oil, wood flour) |

| Sustainability | Very High | Low | Moderate |

| Impact Resistance | High – Ideal for gyms & factories | Moderate – Prone to dents | Moderate – May tear under heavy use |

| Moisture Resistance | Excellent | Good | Poor – Susceptible to water damage |

Need help choosing? Explore flooring comparisons to find the smartest fit for your facility or project.

3. Is Ecore rubber flooring worth the investment?

Yes, Ecore rubber is a smart long-term investment thanks to its unmatched durability and low maintenance needs.

- Reduces cost-per-use – Lasts for decades under heavy traffic

- Minimizes maintenance – Resistant to scuffs, spills, and chemicals

- Saves money by reducing replacement cycles

- LEED-beneficial – May qualify your facility for sustainability credits

Want flooring that works as hard as you do? Check out Ecore’s performance products built to last under pressure.

4. Which industries benefit most from installing Ecore Rubber flooring?

Ecore rubber is ideal for environments that demand safety, durability, and sustainability.

- Fitness & Athletics – For shock absorption and slip resistance in gyms, turf zones, and studios

- Healthcare – Anti-fatigue support and hygiene benefits in rehab and therapy clinics

- Education – Safe surfacing for school gyms and classrooms

- Commercial & Industrial – Tough enough for factories, airports, and high-traffic retail

Designing for performance? Browse industry-specific flooring solutions to match your application needs.

5. How long does Ecore Rubber flooring last under heavy use?

Ecore Rubber flooring is engineered to last 20+ years in demanding environments.

- Vulcanized construction prevents degradation from impact and chemical spills

- Slip-resistant even when wet, reducing safety risks and premature wear

- Withstands 24/7 commercial use without warping or cracking

- Ideal for high-traffic settings like fitness centers, schools, and public spaces

Looking for ultra-durable surfaces? Review our most popular Ecore rubber flooring models designed to go the distance.

6. Does rubber flooring help with sound control in gyms and commercial spaces?

Yes, Ecore rubber has excellent acoustic properties, making it a popular choice for noise-sensitive environments.

- Absorbs airborne and impact noise from dropped weights or foot traffic

- Reduces echo and reverberation in open-plan or multi-floor buildings

- Tested by acoustics professionals in commercial gym installations

- Improves user experience in schools, healthcare, and offices

Want quieter flooring? Browse sound-dampening options within Ecore’s rubber flooring collections.

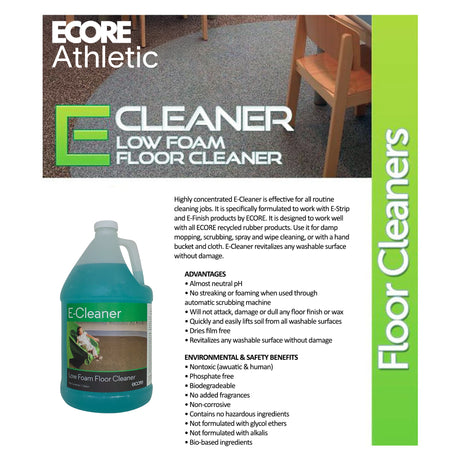

7. Is Ecore Rubber safe for environments with frequent moisture or cleaning chemicals?

Yes, Ecore rubber is highly resistant to moisture and chemical damage.

- Non-porous, won’t absorb liquids or promote mold growth

- Durable under exposure to disinfectants, oils, and cleaning agents

- Ideal for locker rooms, rehab centers, and industrial floors

- Maintains slip resistance and integrity over time

Need flooring that holds up to spills and sanitation? Explore moisture-resistant Ecore rubber solutions for peace of mind.

8. How environmentally friendly is Ecore Rubber compared to other flooring materials?

Ecore Rubber is one of the most eco-friendly flooring options available.

- Made from post-consumer tires, diverting millions of pounds of waste from landfills

- Manufactured with reduced energy and water usage

- Low VOC emissions support indoor air quality and LEED goals

- Many products are recyclable at end-of-life, supporting circular design

Looking to reduce your environmental footprint? Compare recycled rubber flooring collections to find a sustainable solution today.

The Smarter, Stronger Way to Floor

In a world that’s demanding more from our materials—and rightfully so—Ecore rubber hits that sweet spot between innovation and responsibility. It’s not just about recycled content or stylish finishes. It’s about creating surfacing that performs under pressure, cushions where it counts, and lasts when others quit. It’s about turning yesterday’s waste into tomorrow’s wellness, performance, and design.

If you're building something that matters—be it a training facility, clinic, classroom, or commercial space—then give your floors a foundation that works just as hard as the people walking on it. That’s the promise of Ecore.

Ready to Take the Next Step?

At Blue Sky Fitness Supply, we carry a full line of premium Ecore rubber flooring solutions—hand-picked for their quality, performance, and sustainability. Whether you’re designing from the studs up or retrofitting an aging space, our team’s here to help you find the right fit for your goals.

Explore the collection. Ask questions. Get expert guidance from real humans who understand fitness, performance, and design.

Because when you’re investing in flooring, you’re really investing in how a space feels, functions, and lasts.

Start where smart surfaces begin—visit Blue Sky Fitness Supply today to bring high-performance, eco-friendly flooring into your project.